Blow Molding

- Home

- Blow Molding

Plastic Blow Molding

In general, there are three types of blow molding: extrusion blow molding (for hollow bodies), injection blow molding (used in medical applications), and preform blow molding (PET packaging).

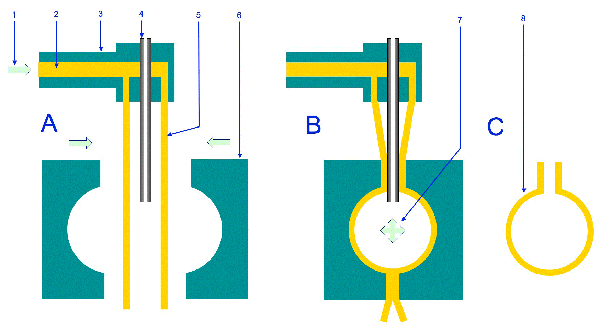

Extrusion blow molding of plastics is a specific manufacturing process used to create hollow plastic parts.

The principle of the process was inspired by glassblowing. Enoch Ferngren and William Kopitke developed the first blow molding machine in 1938.

Process Steps:

- Melting the plastic material and forming a plastic tube through which compressed air can pass.

- The plastic tube is clamped into the mold and filled with compressed air.

- The air pressure pushes the plastic material against the cavity walls.

- Once the plastic cools and solidifies, the mold can be opened.

Advantages:

- A new technological method for creating hollow plastic parts.

- The mold is less expensive compared to plastic injection molding.

- There is no material waste.

Disadvantages:

- The part and equipment costs are higher compared to plastic injection molding.

- It's not possible to mold holes directly — they must be made after blow molding.

- Less precise wall thickness control compared to injection molding.

Application Examples:

Blow molding is specialized in producing hollow plastic parts. Although it is less precise in terms of wall thickness — which is an undefined dimension — it contrasts with injection molding, where all dimensions are predetermined.

Transform your idea into reality

From concept to production - the ELJ Automotive team helps you achieve your goals