Microcellular gas injection (MuCell)

- Home

- Microcellular gas injection (MuCell)

Microcellular Gas Injection (MuCell)

One of the main topics of analysis and study when it comes to optimization is the reduction of the weight of a part or assembly. The intuitive and immediate solutions are changes in geometry or material.

But what else can be changed when there are constraints on modifying the geometry or the material? In search of a solution, engineers turned to the model of aerated chocolate.

While aerated chocolate was introduced by Rowntree’s in 1947, the MuCell technology appeared relatively recently, in 1974, through a U.S. patent titled Mixing Molten Plastic with Gas.

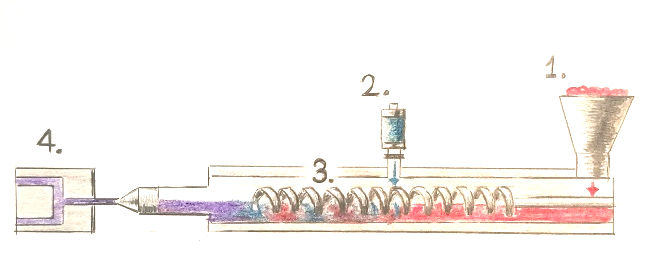

Process Steps

- The polymer is melted and added into the machine.

- In a precise amount, under controlled pressure conditions, gas—nitrogen or carbon dioxide—is introduced and injected into the polymer mass.

- Homogeneous mixing to create a single-phase solution.

- The polymer is injected uniformly into the mold cavity.

Advantages

- Reduction in part weight by up to 20%.

- Reduction in injection cycle time (by 5–10 seconds).

- No significant modifications required to the mold.

Disadvantages

- Tensile strength decreases linearly with material density.

- Poor surface appearance of parts.

- Involves additional investment costs.

Application Examples

Some examples of applications include automotive dashboards, medical devices, storage boxes, home appliances, hand tools, etc.

Transform your idea into reality

From concept to production - the ELJ Automotive team helps you achieve your goals